Lockout/Tagout (LOTO) Procedure: A Comprehensive Guide

Lockout/Tagout (LOTO) procedures safeguard workers from hazardous energy release during equipment servicing and maintenance‚ ensuring OSHA compliance and safety.

Understanding OSHA 1910.147

OSHA Standard 1910.147‚ “The Control of Hazardous Energy (Lockout/Tagout)‚” establishes crucial requirements for controlling energy sources during servicing and maintenance of equipment. This regulation aims to prevent accidental startup or release of hazardous energy‚ protecting employees from potential injuries.

The standard outlines employer responsibilities‚ including developing and implementing a written LOTO program‚ providing employee training‚ and conducting periodic inspections. It details procedures for identifying energy sources‚ isolating equipment‚ and applying lockout/tagout devices. Compliance with 1910.147 is vital for maintaining a safe work environment and avoiding costly OSHA violations‚ as highlighted by frequent citations for LOTO deficiencies.

The Importance of LOTO

Lockout/Tagout (LOTO) is paramount for worker safety‚ preventing severe injuries – and even fatalities – resulting from unexpected energization of equipment. Without proper LOTO procedures‚ employees face risks like crushing‚ amputation‚ electrocution‚ burns‚ and more during maintenance or repair tasks.

Effective LOTO programs minimize workplace accidents‚ reduce lost workdays‚ and improve overall productivity. Adhering to OSHA’s 1910.147 standard isn’t just about compliance; it demonstrates a commitment to employee well-being. Frequent OSHA violations related to LOTO underscore the need for robust training and consistent application of procedures‚ protecting both personnel and the organization from legal and financial repercussions.

Identifying Hazardous Energy Sources

Accurate identification of all energy sources is the cornerstone of a successful LOTO procedure. This extends beyond simply recognizing electrical hazards; it encompasses a comprehensive assessment of all potential energy types. Failing to identify a source can lead to unexpected equipment startup and serious injury.

A thorough hazard assessment must consider stored energy – like that in capacitors‚ springs‚ or elevated positions – as well as readily apparent sources. Recognizing these dangers requires detailed knowledge of the equipment and its operation. Proper documentation of identified energy sources is crucial for developing effective control measures and ensuring consistent LOTO application across all maintenance activities.

Types of Hazardous Energy

Several forms of hazardous energy demand attention during LOTO procedures. Electrical energy is perhaps the most recognized‚ but pneumatic‚ hydraulic‚ and mechanical energies pose significant risks. Stored energy‚ like in capacitors or springs‚ requires specific dissipation techniques.

Gravitational energy (equipment height) and thermal energy (hot surfaces/fluids) also necessitate control. Furthermore‚ chemical energy (pressurized gases/liquids) and even radiant energy must be considered. A complete LOTO program details procedures for safely neutralizing each identified energy type‚ preventing accidental release and ensuring worker protection during maintenance and servicing.

Developing a Written LOTO Program

A comprehensive‚ written Lockout/Tagout (LOTO) program is crucial for OSHA compliance and worker safety. This document should detail specific procedures for controlling hazardous energy sources within your facility. The program must include a clear scope‚ employee responsibilities‚ and step-by-step instructions for safe shutdown‚ isolation‚ and re-energization of equipment.

Detailed equipment-specific procedures are essential‚ alongside training requirements for authorized employees. Regular program review and updates are vital to reflect changes in equipment or processes. PDF resources and templates can aid in program development‚ ensuring all necessary elements are addressed‚ fostering a safe working environment and minimizing potential hazards.

Step 1: Preparation for Shutdown

Prior to any equipment shutdown for maintenance or servicing‚ thorough preparation is paramount. This initial step involves understanding the specific hazards associated with the equipment‚ referencing detailed lockout/tagout procedure PDFs for guidance. Crucially‚ all affected employees must be notified of the impending shutdown‚ ensuring everyone is aware and can take necessary precautions.

A comprehensive equipment hazard assessment is then conducted to identify all potential energy sources – electrical‚ pneumatic‚ hydraulic‚ and others. This assessment informs the subsequent isolation steps‚ guaranteeing a safe working environment. Proper planning‚ utilizing available resources‚ and clear communication are key to a successful and safe shutdown process.

Notification of Affected Employees

Effective communication is vital before initiating any lockout/tagout (LOTO) procedure. All affected employees – those who operate‚ maintain‚ or work near the equipment – must receive clear and concise notification of the planned shutdown. This notification should detail the timing‚ scope‚ and potential hazards associated with the procedure‚ often referencing relevant sections within a lockout/tagout procedure PDF.

Proper notification ensures everyone understands the risks and can take appropriate safety measures. It prevents unexpected startup or release of stored energy‚ safeguarding personnel. Methods include verbal communication‚ written notices‚ and safety briefings‚ all documented for compliance. A well-informed team is a safe team‚ minimizing potential incidents during maintenance.

Equipment Hazard Assessment

A thorough equipment hazard assessment is the cornerstone of a safe lockout/tagout (LOTO) procedure‚ often detailed within a comprehensive lockout/tagout procedure PDF. This assessment identifies all potential energy sources – electrical‚ pneumatic‚ hydraulic‚ thermal‚ gravitational‚ and more – that could pose a risk during servicing or maintenance.

Detailed documentation of these hazards‚ including their magnitude and potential consequences‚ is crucial. The assessment should also pinpoint all energy isolating devices‚ like circuit breakers‚ valves‚ and switches; This process informs the development of specific LOTO steps‚ ensuring all hazards are controlled before work begins‚ protecting employees from accidental energy release and potential injury.

Step 2: Equipment Shutdown & Isolation

Following preparation‚ equipment shutdown and isolation are critical steps‚ often outlined in a detailed lockout/tagout procedure PDF. Begin with normal shutdown procedures as specified by the manufacturer. Subsequently‚ isolate all energy sources – a systematic approach is vital.

For electrical isolation‚ de-energize circuits and lockout/tagout circuit breakers. Non-electrical sources‚ like pneumatics or hydraulics‚ require closing valves and bleeding pressure. Verify zero energy state after isolation. Proper isolation prevents unexpected energization during maintenance‚ safeguarding personnel and ensuring adherence to OSHA’s 1910.147 standard‚ as detailed in comprehensive LOTO documentation.

Proper Shutdown Procedures

Proper shutdown procedures‚ often detailed within a lockout/tagout procedure PDF‚ are foundational to worker safety. These procedures must align with the equipment manufacturer’s recommendations and established company policies. Initiate shutdown using the normal stopping method – avoid emergency stops unless absolutely necessary.

Document each step meticulously. Communicate the shutdown to all affected employees‚ ensuring everyone understands the process. A well-defined shutdown sequence minimizes risks associated with unexpected equipment start-up. Referencing a comprehensive LOTO document ensures consistency and compliance with OSHA standard 1910.147‚ preventing accidental energy release during maintenance or servicing.

Isolating All Energy Sources – Electrical

Isolating electrical energy sources is a critical step‚ often detailed in a lockout/tagout procedure PDF. De-energize circuits at the breaker or disconnect switch‚ never relying solely on switch off functionality. Verify zero energy state with a properly rated voltage tester before proceeding.

Lock out and tag out the energy isolating devices – breakers‚ switches‚ or disconnects – to prevent accidental re-energization. Ensure the tester is functioning correctly before and after verification; A detailed LOTO document will specify acceptable testing methods and qualified personnel. Following these steps‚ as outlined in OSHA 1910.147‚ minimizes the risk of electrocution or arc flash during maintenance.

Isolating All Energy Sources – Non-Electrical (Pneumatic‚ Hydraulic‚ etc.)

Lockout/tagout procedure PDFs emphasize isolating non-electrical sources like pneumatic‚ hydraulic‚ and gravitational energy. Bleed off pressure from pneumatic systems by opening valves and disconnecting air lines. For hydraulic systems‚ lower and secure elevated components‚ and relieve stored pressure.

Block or relieve spring energy‚ and secure gravity-dependent parts. A comprehensive LOTO program‚ often found as a downloadable PDF‚ details specific procedures for each energy type. Verify isolation by attempting to operate the equipment. Proper isolation prevents unexpected movement or release of stored energy‚ safeguarding personnel during maintenance or repair work‚ as per OSHA guidelines.

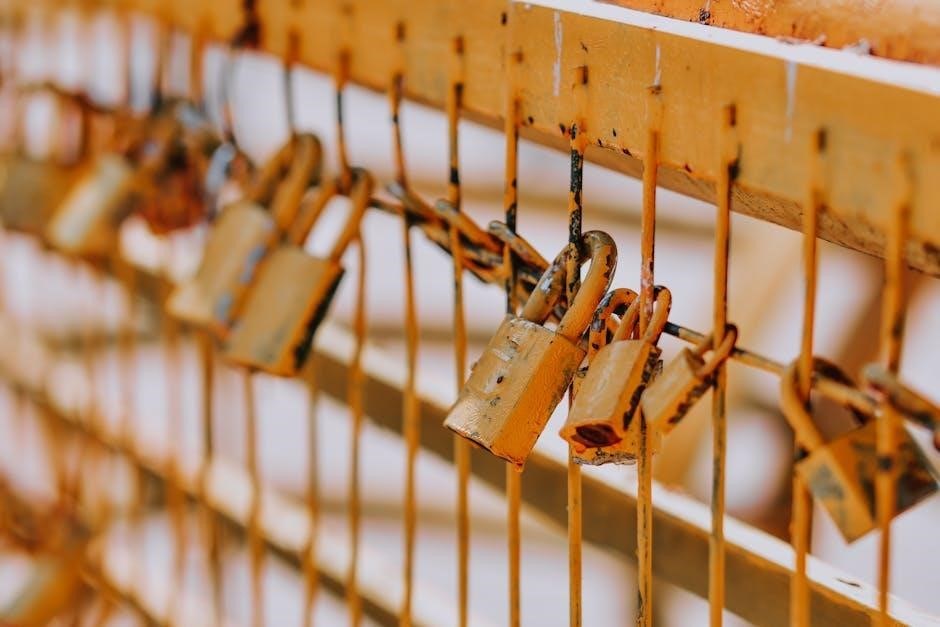

Step 3: Lock and Tag Application

Lockout/tagout procedure PDFs detail the critical step of applying locks and tags to energy-isolating devices. Each authorized employee must affix their personal lock to the device‚ ensuring exclusive control. Tags must clearly state “Do Not Operate‚” identifying the reason for lockout and the responsible personnel.

Lockout devices should be durable and standardized. Tagout is permissible only when lockout isn’t feasible‚ requiring a specific‚ documented procedure. Multiple lockout/tagout scenarios are often illustrated in these PDF guides. Proper lock and tag application prevents accidental re-energization‚ protecting maintenance staff from hazardous energy release during servicing.

Locking Out Energy Isolating Devices

Lockout/tagout procedure PDFs emphasize securing energy-isolating devices – circuit breakers‚ valves‚ disconnect switches – with assigned‚ individual locks. These locks must be robust and resistant to tampering. The PDF guides often showcase various lock types suitable for different devices.

Authorized employees are solely responsible for their lock’s key‚ preventing premature removal. Detailed diagrams within the PDFs illustrate proper lock placement. Confirming positive lock application is crucial before proceeding. Remember‚ each energy source requires a dedicated lock. These documents stress that bypassing or removing another employee’s lock is strictly prohibited‚ ensuring a safe working environment.

Tagout Procedures (When Lockout is Not Possible)

Lockout/tagout procedure PDFs detail tagout as an alternative when lockout isn’t feasible. Tags must clearly display “DO NOT OPERATE‚” the employee’s name‚ and the reason for the tag. These PDFs highlight that tagout provides less protection than lockout‚ requiring increased vigilance.

Tags must be securely attached to the energy-isolating device and be readily visible. Regular inspection of tags is vital‚ as they can be easily removed. The documents emphasize that tagout should only be used when lockout is impossible and with specific managerial approval. A comprehensive PDF will outline the specific circumstances justifying tagout and the heightened safety measures required.

Verification of Isolation

Lockout/tagout procedure PDFs consistently emphasize rigorous verification of isolation. Before commencing work‚ employees must confirm that all hazardous energy sources are effectively isolated. This involves testing the system to ensure it’s completely de-energized – attempting to start the machine or verifying zero voltage.

These PDFs detail specific testing methods for different energy types (electrical‚ pneumatic‚ hydraulic). Verification isn’t complete until all affected personnel confirm the isolation. Documentation of this verification process is crucial for audit trails and demonstrating compliance. A properly formatted PDF will include checklists and sign-off sheets for this critical step‚ ensuring a safe working environment.

Testing the Isolated System

Lockout/tagout procedure PDFs universally stress thorough system testing. After applying locks and tags‚ verify the effective isolation of all energy sources. For electrical systems‚ use a calibrated voltage meter to confirm zero energy state – never rely on sight alone. Pneumatic and hydraulic systems require confirming pressure release and inability to operate;

PDF resources often include detailed testing checklists specific to equipment types. Employees performing the test must be qualified and trained. Documenting test results‚ including date‚ time‚ and tester’s signature‚ is vital. Any residual energy detected necessitates re-evaluation of the LOTO procedure and immediate correction before work begins‚ as highlighted in comprehensive LOTO guides.

Group Lockout/Tagout Procedures

Lockout/tagout procedure PDFs detail group LOTO for complex equipment requiring multiple personnel. Each worker applies their own personal lock and tag to the energy isolating devices. A group lockout box may be used‚ but each individual retains control over their locking device.

Clear communication is paramount; a designated person coordinates the process. The final step before work begins involves verifying isolation with each worker present. Removal of locks/tags requires the consent of all involved‚ ensuring no one restarts the equipment prematurely. Comprehensive guides emphasize accountability and prevent accidental energization during group maintenance activities.

Shift Changes and LOTO

Lockout/tagout procedure PDFs stress the critical importance of LOTO continuity during shift changes. The on-coming shift must be fully informed about all active LOTO situations‚ including the equipment involved‚ hazards‚ and the locks/tags applied.

A thorough transfer of information is essential – never assume the next shift is aware. Detailed documentation‚ readily available‚ is vital. The outgoing shift confirms the LOTO status with the incoming shift‚ ensuring no unauthorized removal occurs. Proper handover prevents accidental energization and maintains worker safety throughout all operational periods‚ as highlighted in OSHA standards.

LOTO for Contractors

Lockout/tagout procedure PDFs emphasize that host employers are responsible for informing contractors about existing LOTO procedures and hazardous energy sources. Contractors must adhere to the site’s LOTO program‚ and often‚ provide their own locks and tags – uniquely identified.

Clear communication and coordination are paramount. Contractors should participate in hazard assessments and receive training on the specific LOTO protocols for the equipment they’ll be servicing. The host employer verifies the contractor’s LOTO implementation. This collaborative approach ensures consistent safety standards and prevents incidents involving external personnel‚ aligning with OSHA’s multi-employer worksite guidelines.

Common OSHA Violations Related to LOTO

Lockout/tagout procedure PDFs frequently highlight common OSHA violations. These include failure to establish and implement a comprehensive written LOTO program‚ inadequate employee training‚ and a lack of periodic inspections to ensure program effectiveness.

Specifically‚ violations often involve failing to identify all hazardous energy sources‚ improper lock and tag application‚ and insufficient procedures for group lockout scenarios. Additionally‚ neglecting to provide affected employees with the necessary information about the program is a frequent issue. Corrective actions often require program revisions‚ retraining‚ and diligent enforcement of established protocols to avoid costly citations.

LOTO Procedure PDF Resources & Templates

Lockout/tagout procedure PDFs are readily available from OSHA’s website and various safety organizations‚ offering detailed guidance and customizable templates. These resources often include sample written programs‚ training materials‚ and checklists for verifying LOTO procedures.

Many templates facilitate hazard assessments‚ energy source identification‚ and the creation of equipment-specific LOTO steps. Pest management professional resources also offer tailored LOTO guidance. Utilizing these PDFs ensures compliance with OSHA Standard 1910.147 and promotes a safer work environment. Downloadable forms streamline documentation and improve the overall effectiveness of your LOTO program.